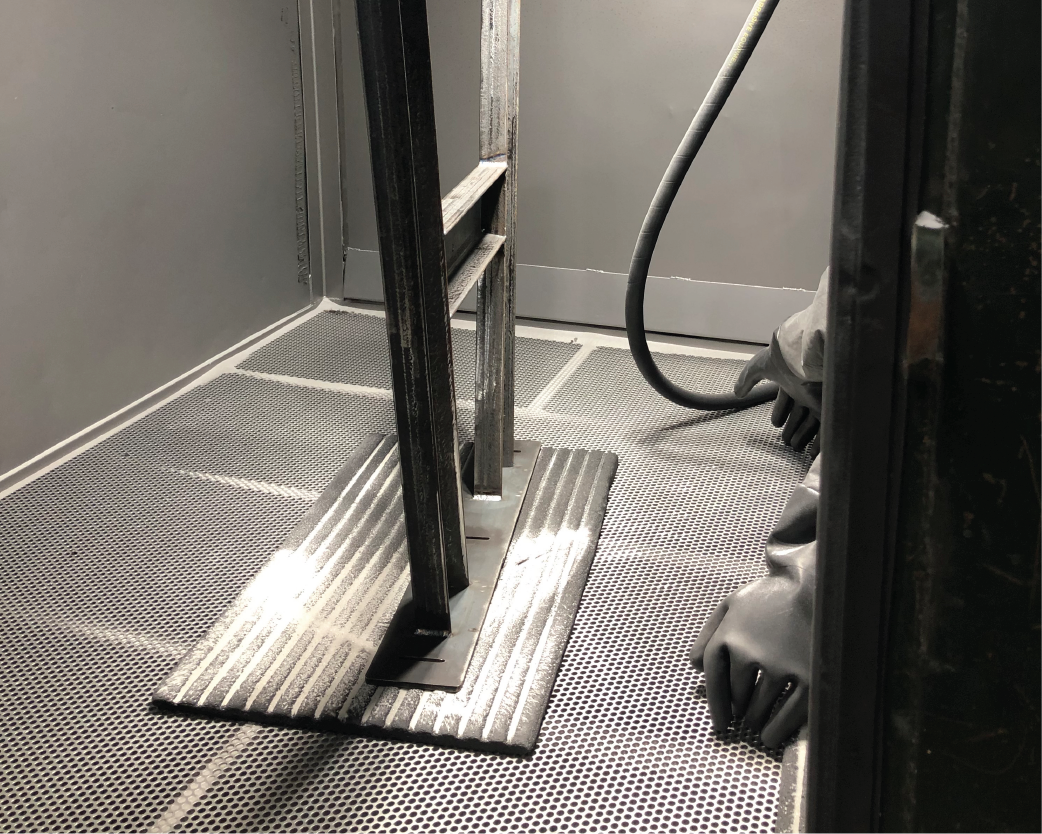

At Axis Custom Coatings proper part preparation is key to the powder coating process. We have the the experience, equipment and procedures to clean,

apply the correct conversion coating, seal, mask and properly prepare aluminum and steel parts for the application of electrostatic powder coatings.

5-Stage Part Preparation Process:

- Clean off all residual oils and soils as well as any rust

- Chemically etch the surface to create a profile for powder to adhere

- Apply a Zinc Phosphate conversion coating for further protection

- Rinse the surface of all chemicals used and seal the surface

- Final inspection of parts before powder coating

We ensure a proper pre-treatment of a product surface prior to powder coating to ensure you do not have issues like fish eye and

surface contaminants when you powder coat your part.